Power Factor Correction

Our team of qualified and experienced technicians provide power quality solutions to commercial and industrial customers throughout Australia.

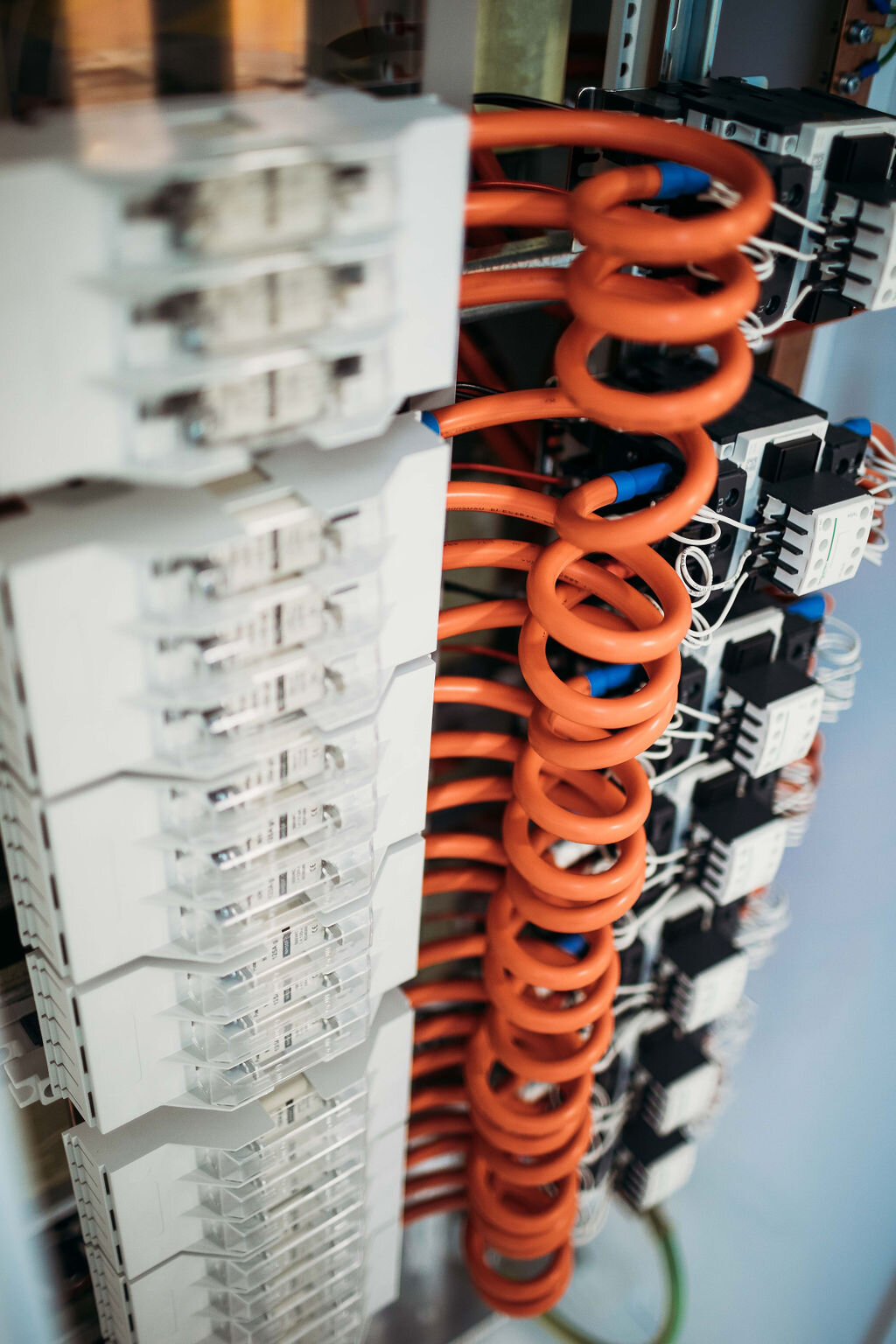

We design, install, maintain and repair Power Factor Correction (PFC) equipment and we work intimately with some of the best manufacturers in the world.

PFC is increasingly used to alleviate technical problems associated with poor power quality, reduce kVA demand charges and avoid capital outlay when looking to increase capacity. GFE Group are the experts when it comes to PFC. We identify energy management opportunities and design, implement and commission a PFC solution that results in cost savings and greater efficiencies.

By increasing your power factor, you can reduce your electricity bills through lower monthly demand and capacity charges. Typically payback periods for PFC are between one and three years. Given the life expectancy of PFC equipment and the potential savings, it can be a very worthwhile investment. It may also help to avoid costly infrastructure upgrades by lowering the existing electrical demand on your system and improving efficiency stability.

Why Increase Your Power Factor?

Inefficient electricity systems tend to use a large quantity of ‘reactive’ power (kVAr), which represents the power lost in the operation of inductive equipment such as transformers and electric motors. This invariably increases the total power load represented by your kVA – and reduces your overall energy efficiency or ‘power factor’. Power factor is the ratio between your kVA, or total power load, and your kW, or the actual power working for your business. Power factor is measured on a scale between zero and one, with 1.0 representing optimal energy efficiency.

If your power factor dips below 0.9, you are not only losing energy and money, but you could also be damaging your electrical equipment.

Top 5 Reasons To Consider Power Factor Correction

-

Reduce Demand Chargers (Lower Your Bill)

Networks charge large businesses for the demand they place on the electricity grid. So if you’re being charged a network demand charge, it pays to improve your power factor.

-

Improve Voltage

Low power factor may cause power losses and voltage drops, which can contribute to overheating and failure of motors and other equipment. A lower power factor causes a higher current flow for a given load. As the line current increases the voltage drop in the conductor increases, which may result in a lower voltage at the equipment.

-

Increase Load Carrying Capabilities

Load factor is a measure of the utilisation rate, or efficiency of electrical energy usage; a high load factor indicates that load is using the electric system more efficiently, whereas consumers or generators that underutilise the electric distribution will have a low load factor. You want your power factor to be as close to 1 as possible.

-

Reduce Power System Loses

By reducing the circulation of reactive power through the line, capacitors reduce the line current and associated power losses, which is how capacitors save energy. Line losses can represent approximately 10% of the total active power transmitted in the electrical systems. A capacitor can save one-third of a line’s power losses.

-

Reduce Carbon Footprint

It is possible to save around 100kg of CO2 per year for every kVAR (reactive power). Is that really a big deal? Yes; this is the same amount of CO2 released into the atmosphere when your car burns 40 litres of fuel. So, capacitors prevent hundreds of thousands of tons of CO2 emissions worldwide from being discharged into the air, improving your carbon footprint.

Case Study

Bunnings

GFE Group partnered with Bunnings to supply and install 21 Power Factor Correction systems across Queensland and New South Wales. As a result of these installations Bunnings are now receiving lower demand changes due to their improved power factor.

ON AVERAGE OUR CUSTOMERS SAVE $10,000 - $75,000

You can trust us to know how to improve your Power Factor and advise on the best equipment to deliver your business a tailored and cost effective solution.

GFE Group have 4 steps, which guide businesses through the Power Factor Correction setup process.

Step 1

Asking a set of key questions to decipher if a business is effected while then educating businesses on changes and demand charges on their electricity bill.

Step 2

Assess interval data from the retailer and model how the extra charges are effecting the businesses.

Step 3

Present possible solution options of savings and cost modelling with no obligation.

Step 4

If a suitable solution is found, GFE Group can implement the full turn key solution.